Methods for safe operation of slitting and slitting units

Preparation

1. Check whether there are any abnormalities in each component of the steel slitting machine units.

2. Check whether each control switch and electrical button is in the normal position.

3. Turn on the power and turn on the cooling water and compressed air switches.

4. Check whether the voltage, air pressure, and pressure of the hydraulic station are normal.

5. Turn on the oiling machine, adjust the amount of oiling, and check the oiling situation of the upper and lower blade beams.

Loading materials

1. When loading materials, the commander must stand in a place with an escape route and confirm that no danger will occur before he can command the crane to lift or lower.

2. Place the steel coil in the center of the loading saddle or trolley to avoid rolling over and injuring people or equipment.

3. When the inner diameter of the steel coil is larger than the uncoiler drum, the pads on the drum must be fixed in order before loading.

4. When lowering the pressure roller or pinch roller of the decoiler, make sure that no one is touching the pressure roller or pinch roller.

5. When uncoiling and unpacking, press the steel coil leader on the trolley, and operate carefully to prevent the packaging strip and leader from jumping up and injuring people when cutting.

6. When cutting the board head, it is not allowed to put your hands under the shearing machine.

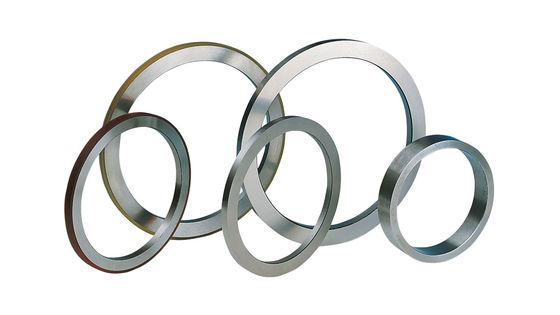

Tool change

1. Before changing the slitting blades, slitting spacers, the operating mode of the unit must be converted from linked action to single action.

2. When raising the cutter axis, do not raise it too high to avoid damaging the arch.

3. When changing the slitting blades, slitting spacer, no one is allowed to rotate the tool shaft, and irrelevant personnel should stay away from the operating buttons.

4. It is prohibited to use a wrench to hook the nut or rotate the cutter shaft to remove or install the hydraulic nut.

5. When disassembling and installing the slitting knife sheath, be careful and use both hands.

6. When installing the slitting blade, be careful to avoid cutting your hands with the slitting blade. Do not use slitting blades with chipped edges or obtuse angles.

7. After changing the slitting knife according to the requirements of the plan sheet, carefully check the slitting width. Then try to trim the edge manually, Check the trimming quality.

Operation

1. Only after getting approval from all parts can the belt be worn. Be sure to run slowly when threading, and be careful to send the edge wire to the edge wire pinch roller to avoid pinching or cutting your fingers.

2. After raising the pressure roller of the edge collecting machine, hang the edge wire in the edge wire pool on the rotating shaft. After the operator leaves the edge machine area, he lowers the pressure roller and starts winding.

3. After threading is completed, check whether the upper and lower plates of the steel belt are scratched, imprinted, and oiled evenly.

4. After checking, the main control should tell other personnel to retreat to a safe range and increase the process speed.

5. When the unit is running, no one is allowed to touch the running steel belt and rolling parts of the unit. It is not allowed to cross or step over the unit.

6. When problems such as broken edge wires or edge warping occur during the production process, the operating speed must be reduced or the machine must be stopped, and the solution can only be solved after ensuring safety. Leave the danger area immediately after the treatment is completed.

7. When collecting the edge yarn, do not pass or stay near the edge collecting machine.

8. When the unit is running, do not stay in front of the uncoiler and rewinder to avoid breaking the belt and injuring people.

9. During the production process, pay close attention to the quality of the board surface, and deal with any abnormalities in time.

Reeling

1. After coiling, be sure to press the steel strip with a press frame and turn the strip head to the top of the trolley.

Only then can it be packaged. Avoid jumping up and injuring others.

2. According to the different thickness of the steel belt, use plastic belt if it is less than 1.5, and use iron packaging belt if it is more than 1.5.

3. When there are narrow straps for packaging, two special iron rods should be inserted on both sides of the trolley to cooperate with each other for packaging to prevent the narrow straps from falling down and injuring people and equipment.

4. When lifting the product, put on a nylon protective cover to protect the side surface of the steel belt from being bruised.

5. When lifting the head and tail, be careful to direct the crane to move slowly to prevent it from falling into the ditch and damaging the oil pipes and wires.

6. When weighing, lift and lower gently to ensure that the steel coils will not overflow and the scale will be safe.

7. Choose as wide an edge material as possible to bundle the edge wire. It is recommended to control the bundle within 400 kilograms.

8. When hanging the edge wire, try not to pass it through the unit. If it is unavoidable, choose to pass it through the looper. Never pass over the operating platform.

Equipment maintenance and environmental safety

1. The roller surface must be cleaned when the machine is stopped. The pinch roller should be opened to a larger opening and use inching operation.

2. When cleaning the electrostatic oiling machine, be sure to turn off the power and use a special discharge rod to discharge it before operation.

3. No one is allowed to stand when the front and rear loopers are suspended in the air. When working in the tunnels of the unit, someone must guard it to prevent others from misoperation.

4. When repairing or maintaining the equipment, cut off the power supply to this part.

5. Clean and maintain all parts of the equipment regularly every week.

6. Debris in the production workshop must be sorted out in a timely manner to the designated location and placed neatly according to regulations.

7. Keep safe passages clear at all times. Do not stack items on top of firefighting equipment.

8. Always check whether the operating pressure and validity period of the rescue equipment are within the specified range.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!