The main application range and main composition of the electrical control system of the slitting and slitting unit, as well as the working principle of each component are as follows. Disc shear: The main process equipment of the unit is used to complete the longitudinal cutting of the strip and to Cut off the redundant parts on both sides of the incoming aluminum plate or the parts whose quality does not meet the requirements, so that the left and right end faces of the finished roll meet the quality requirements.

The electrical control system of the slitting and slitting unit is mainly used in material slitting and coiling control systems in similar industries such as steel plate steel strip, stainless steel plate, aluminum foil in ferrous metallurgy, copper plate and copper strip metal in non-ferrous metallurgy. Due to the high speed of the machine, if the scrap edge is improperly processed and the belt is broken, it will directly affect the production.

The main components that make up the electrical control system of the slitting machine are: uncoiler, speed measuring roller, pinch roller, head cutter, disc cutter, looper pit, tension pad, tension roller (machine), tail cutter, coiling machine.

1. The main functions and control requirements are as follows:

2. Uncoiler: used to open the incoming aluminum coil, provide the uncoiling tension under various possible coil diameters, calculate the diameter of the aluminum coil on the uncoiler in real time, and control the constant tension of the uncoiling section.

3. Pinch roller: when threading the belt, assist the uncoiler to pass the aluminum plate to the direction of the coiler. When the machine train is working, the upper roller can be lifted without participating in the work, and the upper roller can also be pressed down to assist the disc cutter. The forward tension of the uncoiling section prevents the disc cutter from slipping.

4. Cutting head scissors: used to handle the lead to meet the process and operation requirements.

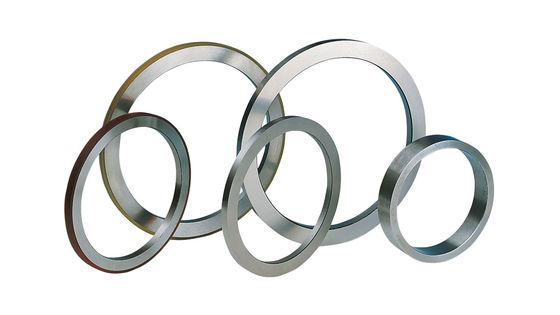

5. Disc cutter: It is the main process equipment of the machine line, used to complete the longitudinal cutting of the strip, and at the same time, it is used to cut off the excess parts on both sides of the incoming aluminum plate or the part that does not meet the requirements, so that the finished coil The left and right end faces meet the quality requirements.

6. Looper pit: It is used to release the influence of different transverse internal stresses in the incoming aluminum coil on the strip after longitudinal shearing.

7. Tension pad: It is the main equipment that provides tension in the winding section, and it is also one of the main equipment that affects whether the finished roll can be "rolled up".

8. Tension roller: It provides the tension of the winding section together with the tension pad. It is a "window" for dynamic tension adjustment, which can be used to realize tension shaver control and increase various tension compensations, such as static compensation, dynamic compensation, etc.

9. Speed measuring roller: It is the measuring point of the linear speed of the coiling section, and it is also one of the basis for calculating the coil diameter of the coiler, and its importance is self-evident.

10. Coiler: It is a place to rewind the finished product after longitudinal shearing, and it is also a device for stabilizing the linear speed of the coiling section. Constant linear speed control is required. Its stability control is the top priority of the entire system. .

Design, research and development, production, sales, export trade and export supporting services in one: (metal coil precision slitting production line, cross-cutting production line, high-speed flying shear production line, high-speed bending and straightening production line)

Slitting and slitting unit machine application: cold rolled coil, galvanized coil, pickled coil, color coated coil, stainless steel coil, aluminum coil, copper coil, iron coil, electrolytic galvanized coil, hot Dip galvanized coils, silicon steel coils, hot-rolled coils, color-coated coils, etc.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!