Operational Progress :

Steel-choosing→Blanking →Forging Steel →Rough Processing →Heat treatment →Finishing→Testing

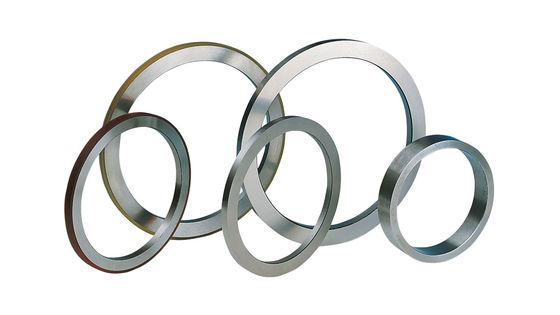

Knives are available with polished side faces ,High cost performance ,Punctual delivery .

Materials : 9CrSi ,6CrW2Si , H13 ,Cr12MoV ,G1 , G2 ,G3 and etc .

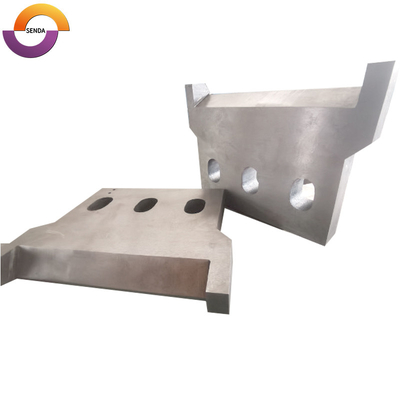

Senda Hydraulic Shearing knife for cutting rebars are mainly applied to shearing machine, bar mills, flying shears for the steel making plants, metal rebars factories.

| Brand |

Senda |

| Country of Origin |

China |

| Material |

H12, H13K, HMB etc |

| Hardness |

HRC 52~56 |

| Working temperature |

max can work under 1100 Centigrade |

| Application |

iron rebars factory |

Advantage:

1. Different materials of flying shear blades can work stable under 900 Centigrade, 1000 Centigrade and 1100 Centigrade.

2. Liquid nitrogen -196degree cold treatment ensure the hardness and toughness

Application of the flying shear knife for cutting rebars:

1. Deforming the iron rebars under high temperature.

FAQ

Q: how to select the right material?

A: According to the application: the cutting metal, strength and the thickness, we can provide our recommendation.

Q: How do you control the knife quality?

1.100% Raw material selected from our suppliers, domestic and overseas.

2.Experienced forging, pressing, heat-treatment and CNC.

3.100% manual inspections before delivery.

Senda starting from 1998, focus on the quality of products and provide better service. Now we have over 100 workers, CNC lathes, High precision internal and external circular grinding machines, heat-treatment furnaces grinding machines and inspection machines.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!