Product Description:

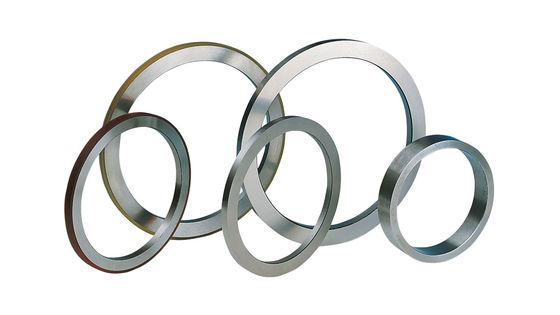

If you're looking for high-quality blades for cutting iron bars in the steel factory, Senda has the perfect solution for you. Our rebars shear blade is specifically designed to cut through steel rebar with ease, making it the ideal choice for the concrete industry.

Our rebar cutting blades are of the highest quality, and we offer cutter blocks and shear knives that are compatible with all makes and models of cutters. You can easily find the right blades for your equipment right here on our website.

Our flying shear blades can withstand temperatures as high as 1100 degrees, making them reliable even in the hottest of working conditions. We achieve this through process-controlled hardening plants that ensure our fly shear knives are heat-treated to perfection. The material and hardness of our blades are matched to the specific application, giving you the best performance possible.

Features:

Senda Brand Steel Making Materials

Senda is a brand of materials used in the steel making industry. The materials are sourced from China.

The specific materials used in Senda products include H13K, HMY, and HMB.

The hardness rating for Senda materials is between HRC 53-55.

Senda materials can withstand high temperatures, with a maximum working temperature of 1100 Centigrade.

The primary application for Senda materials is in steel making factories.

Applications:

The high temperature can cause deformation of steel rods and rebars. When the temperature rises, the metal expands, and this expansion can cause the steel to bend, warp, or twist. This deformation can compromise the structural integrity and durability of buildings, bridges, and other concrete structures that rely on steel reinforcements.

One way to prevent this deformation is by using special heat-resistant steel as reinforcements in construction projects. Heat-resistant steel is designed to withstand high temperatures and maintain its shape and strength even under extreme thermal conditions. This can help ensure the safety and reliability of the structures in high-temperature environments.

Another solution is to use fire-resistant coatings on the steel rods and rebars. These coatings can provide a protective layer that slows down the heating process and reduces the risk of deformation. The coatings can also help prevent corrosion and rust, which can further weaken the steel and compromise the structure's stability.

Overall, it is crucial to consider the potential effects of high temperature on steel reinforcements and take adequate measures to prevent deformation. This can help ensure the safety, longevity, and sustainability of the structures we build.

Packing and Shipping:

Product Packaging:

- One Flying Shear Blade in a protective plastic sleeve

- Blade is placed in a sturdy cardboard box with foam inserts for added protection

- Box is labeled with product name and specifications

Product Shipping:

- Ships via standard ground shipping within 2 business days of order confirmation

- Shipping cost is calculated based on weight and destination

- Tracking information will be provided once the product has shipped

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!