Product Description:

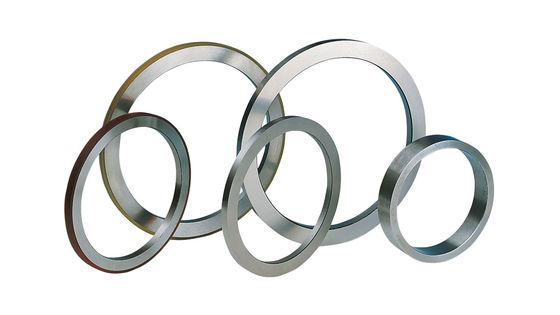

Surface mirror finishing rolling shear knives are designed for slitting non-ferrous metals. These rotary shear knives, produced by Senda for metal coil processing, are primarily used on slitter machines. They are constructed from a variety of high-quality materials, including forged tool steels, high-speed steels, Neuenkamp's special materials, and powder-metallurgically produced high-performance steels.

The production process involves heat-treating the roll shear knives in advanced hardening plants where the process is closely controlled. The material used and the hardness of the knives are carefully selected to suit the specific application they are intended for. This ensures optimum performance and durability in metal coil processing.

Applications:

Application of the Rotary slitting knives for metal coil processing:

1. Normally for hot rolling: 1mm~12.7mm carbon steel coils, stainless steel plates sheet, GI, PO etc.

2. Normally for cold rolling: 0.02mm~3.2mm carbon steel plates, stainless steel plates, galvanized plates, GI, PO etc.

Customization:

Product Customization Services for the Rotary Slitter Blades:

- Brand Name: SENDA

- Model Number: SD005

- Place of Origin: China

- Certification: ISO9001

- Minimum Order Quantity: 10

- Price: USD15

- Packaging Details: Waterproof Plastic+Cardboard+Wooden Case /Pallet

- Delivery Time: 20 days

- Payment Terms: L/C T/T D/P PAYPAL Western Union

- Supply Ability: 200PCS/Month

- Hardness: HRC62-64, HRC58-60

- Size: Customized

- Application: Rotary Slitter Steel Coils Cutting

- Shape: Round

- Thickness tolerance: 0.001mm-0.005mm

- Keywords: tungsten cutting blade, carbide circular cutter, industrial razor blades

Support and Services:

Our Product Technical Support team for Rotary Slitter Blades is dedicated to providing expert assistance and guidance to ensure optimal performance and efficiency of the product. Our team of professionals is well-equipped to address any technical queries, troubleshoot issues, and offer solutions to enhance the functionality of the Rotary Slitter Blades.

In addition to technical support, we also offer a range of services related to Rotary Slitter Blades, including maintenance, sharpening, and blade replacement. Our service team is trained to handle all aspects of maintenance and repair to prolong the lifespan of the blades and maintain their cutting precision.

Packing and Shipping:

Product Packaging and Shipping for Rotary Slitter Blades:

Each set of rotary slitter blades is carefully packaged in a sturdy cardboard box to ensure safe delivery. The blades are wrapped in protective foam to prevent any damage during transit.

For shipping, we use reliable courier services to guarantee timely delivery. Each package is securely sealed and labeled with the necessary information for easy identification.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!